Metal casting and additive manufacturing are the two most common methods of producing large-scale metal parts. Metal casting involves pouring molten metal into a mold and letting it solidify, while additive manufacturing simply builds up layers of material using metal wire heated with a laser.

One of the main shortcomings of metal casting is that it is limited by the geometry and complexity of the mold. Additionally, casting has a limited material selection and properties due to the compatibility with the mold material and the casting process. The mold has to be designed and fabricated before the casting process, which can be time-consuming and costly. The mold also has to be able to withstand high temperatures and pressures and allow for easy removal of the solidified part. This means that some shapes and features may be difficult or impossible to cast, such as hollow structures, thin walls, intricate details or internal channels. Metal casting also produces a lot of waste material, as the excess metal has to be ground off. Whereas, additive manufacturing can produce near-net-shaped parts with high complexity, accuracy and resolution, as well as parts with internal cavities, channels or lattice structures.

The other shortcomings of metal casting are that it is difficult to control the microstructure and properties of the metal during the solidification process. The cooling rate, temperature gradient and composition of the metal can affect the final part’s grain size, porosity, phase distribution and mechanical properties. Metal casting can also introduce defects such as shrinkage, warpage, porosity, impurities or sand/slag inclusions, which can compromise the quality and performance of the part.

Now how does that compare to ADDere?

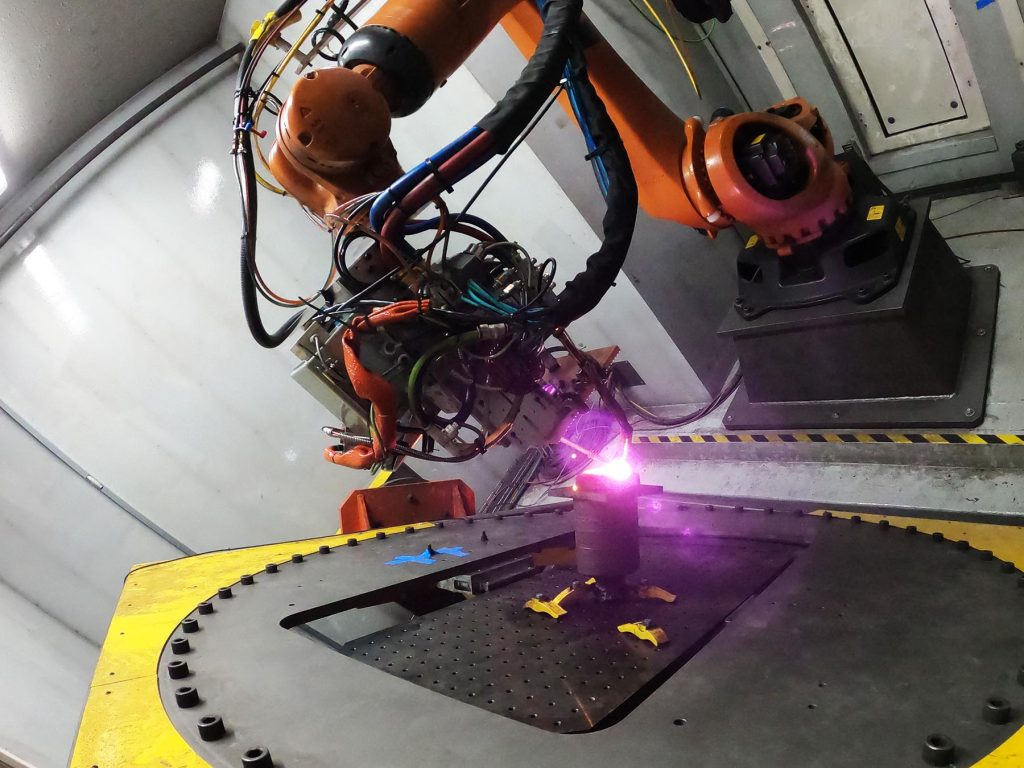

ADDere’s additive manufacturing process offers more control over the microstructure and properties of the metal wire during the layer-by-layer deposition process. The laser can precisely control the temperature, energy and speed of the wire melting, resulting in a finer and more uniform grain structure. Additive manufacturing can also produce near-net-shaped parts with tailored properties by varying the process parameters or the material composition within a single part.

Another factor that manufacturers should consider is that traditional metal casting has a more negative impact on the environment than additive manufacturing, through the use of natural gas and high energy consumption from the melting process. It’s also a dirtier, hotter and more dangerous process for human workers, whereas ADDere is a self-contained system that’s completely safe to operate.

Metal casting is more suitable for the mass production of simple and low-cost parts. At the same time, additive manufacturing is more suitable for prototyping or customized production of complex and high-performance parts. Both methods require careful consideration of the design specifications, material selection, process parameters, quality control and post-processing techniques to ensure optimal results.

If you are looking at manufacturing low-run, custom or prototype parts then additive manufacturing will provide your process with a solid return on investment and reduced environmental impact when compared to casting. Contact us today and we can guide you through the process and how best to proceed.