In today’s competitive and fast-paced market, manufacturers need to keep up with the changing demands of their customers and deliver products quickly and efficiently. However, traditional warehousing methods, such as Just In Case (JIC) manufacturing, can pose several challenges and limitations for manufacturers. JIC manufacturing involves producing and storing large quantities of products in anticipation of future demand, which requires a lot of warehouse space, inventory management, and material resources. Moreover, JIC manufacturing can lead to overstocking, understocking or obsolescence of products, depending on the fluctuations of customer preferences and market trends.

To overcome these challenges, many manufacturers are turning to digital inventories and Just In Time (JIT) manufacturing or lean manufacturing. JIT manufacturing involves producing products only when they are needed, which reduces the need for warehouse space, inventory costs and material waste. JIT manufacturing also allows manufacturers to respond more flexibly and quickly to customer orders and market changes. However, JIT manufacturing requires a reliable and efficient way to access and produce the products on demand, without compromising on quality or variety. This is where digital inventories come in.

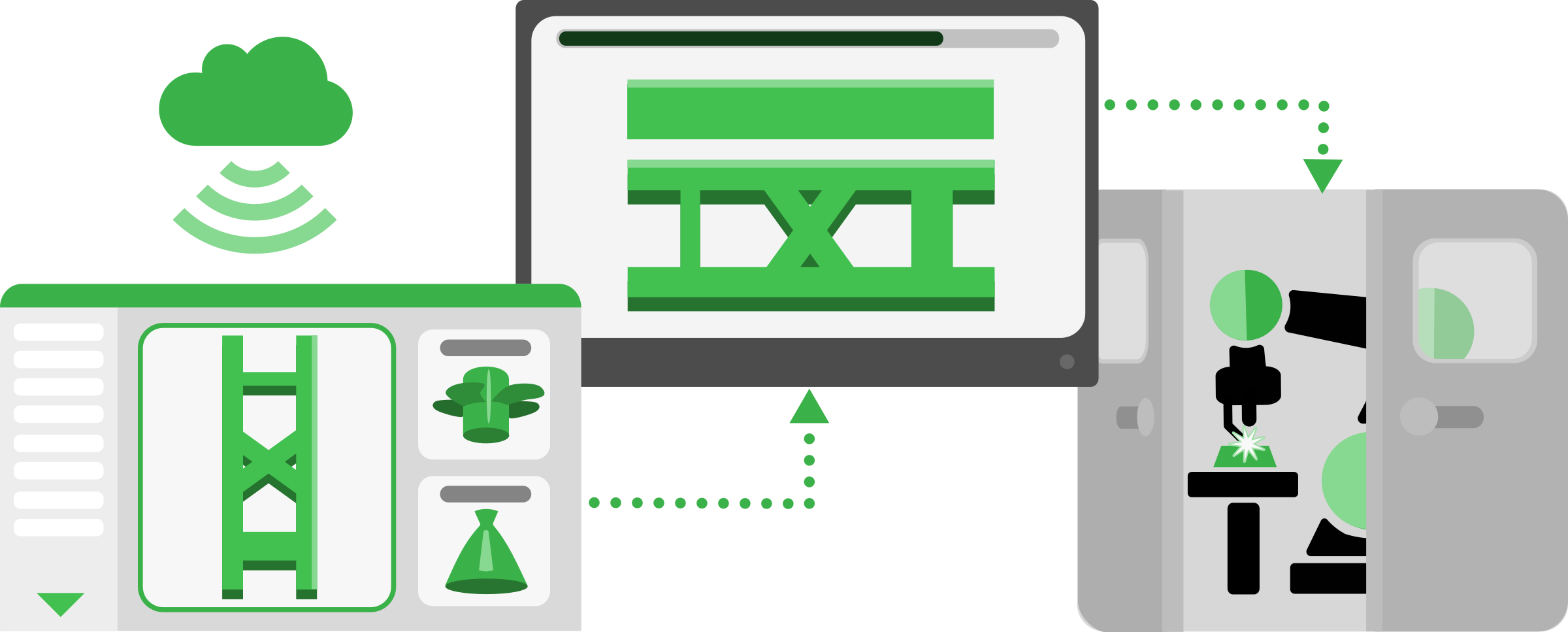

A digital inventory paired with an ADDere Additive Manufacturing System can be a potential sweet spot for manufacturers of all sizes and capacities. Additive manufacturing enables manufacturers to create complex and customized products from digital models, using various materials and processes. By integrating ADDere with a digital inventory system, manufacturers can create a digital warehouse that offers several advantages over traditional warehousing methods.

📦 Keeping Inventory Levels Manageable

A digital inventory helps manufacturers avoid overstocking or understocking products by using advanced forecasting and predictive analytics tools that can optimize inventory buffer levels based on current and future demand. A digital inventory also allows manufacturers to reduce material waste and extensive physical warehousing by enabling them to manufacture only the products that are requested on-demand by customers.

🦺 Eliminates Safety Concerns

Having a completely digital warehouse and inventory would eliminate the hazards typically associated with traditional warehouses by reducing the exposure of workers to hazardous materials and dangerous equipment. A digital warehouse can also improve the safety of products by ensuring that they are produced according to up-to-date standards and quality specifications.

📋 Providing Customers with More Options

By producing products and parts on demand a digital inventory can provide customers with more product options by enabling manufacturers to offer more product variety and part customization. This in turn will also reduce delivery times and associated costs by producing products closer to the point of distribution.

🌳 Beneficial to the Environment

In producing the products closer to the point of delivery, the environmental impact of transporting products would be lessened. Typically, a part would need to be shipped from a regional distribution center or even from overseas, both of which will produce carbon emissions from whatever mode of transportation they utilize.

A digital inventory is an innovative solution that can help manufacturers overcome the limitations and challenges of traditional warehousing methods. By adopting a digital inventory approach, manufacturers can leverage the benefits of ADDere’s additive manufacturing systems to create a more efficient, flexible and responsive production system that can meet the needs and expectations of their customers.

If your business lacks the means to invest in a warehouse or is drowning under a large stockpile of parts, then an ADDere additive system supported by a digital inventory could be the answer for you. Contact us today and speak to one of our additive experts to lay the groundwork for your business’s continued success.