ADDere Hot Wire System

ADDere's dependable next-level material delivery system

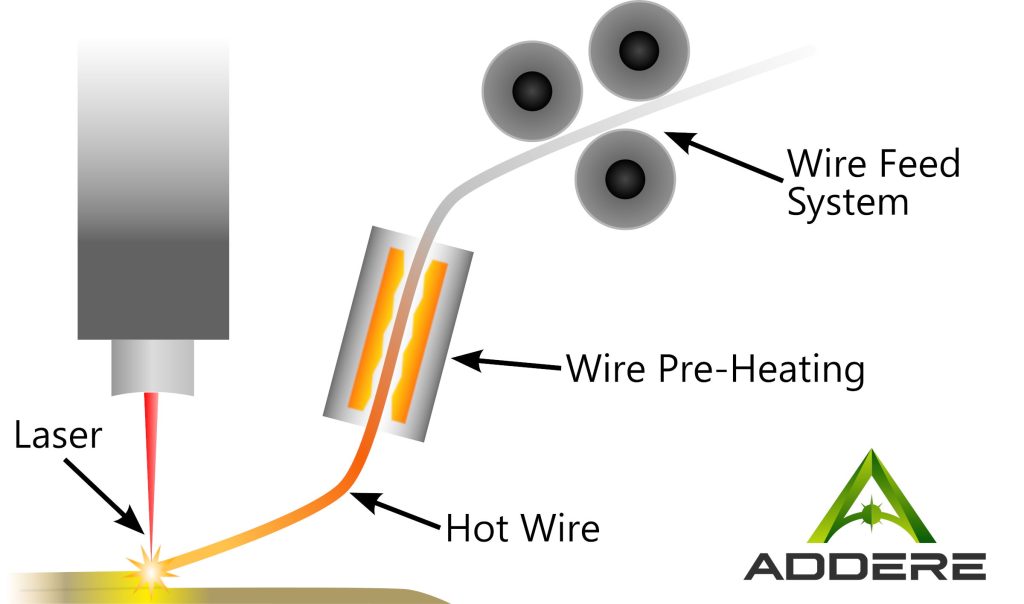

ADDere’s laser-wire material delivery employs a safe and carefully regulated wire delivery system that contains numerous wire drive units that work together, in a push-pull action, to produce the proper quantity of wire needed at the point of contact. The wire delivery system includes hot wire integration, improving deposition rates by 20-40% and metallurgical properties by pre-heating the wire. The hot wire system is powered by a 300 to 600 amp power source with the voltage and current tracked by the closed-loop feedback control. Custom profiles are utilized depending on the type of wire material that will provide clean and reliable results.

The material delivery system tracks the build progress using a secondary laser and adjusts the material supply as needed. Components are assembled utilizing safe and easy-to-use interchangeable spools of metal wire. Allowing for 100% of the wire material actually being used in the build with no material wasted. The metal wire feedstock can be of any weldable metal, including carbon steel, stainless steel, Inconel, Hastelloy, Invar, Titanium and more.

ADDere’s hot wire delivery system comes standard with the ADDere systems and engines. If you would like to know more about this or any of our other products or services, contact us today.

do you want to learn more about ADDere's products and services?

From common metals to superalloys

Materials ADDere Prints

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from