ADDere Additive Engines

ADDere has engines that can power your additive manufacturing needs

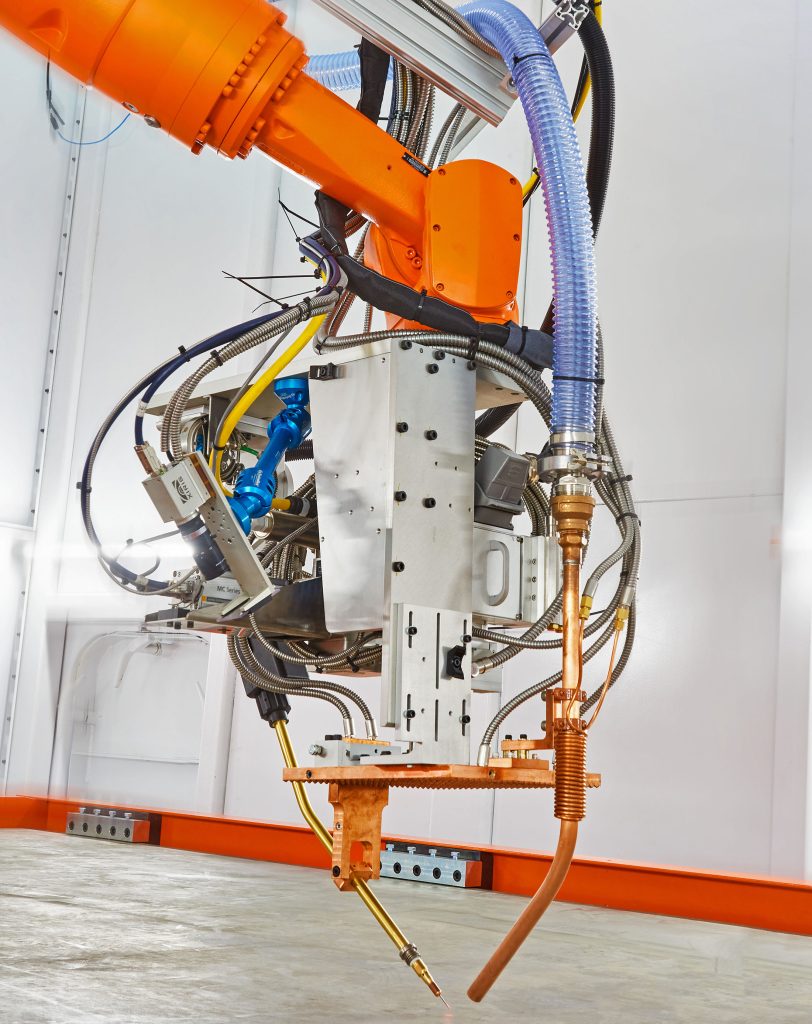

Scanner / Side Wire

| Laser Power (max) | 20kW Laser |

| Wire Size | 0.6-1.6mm (.023-.063) |

| Hot Wire Compliant | yes |

| Minimum Single Bead Thickness | 4mm |

| Maximum Single Bead Thickness | 20mm |

| Maximum Deposition Rate | 30lb/hr* |

| Water Cooled | yes |

| Vary Bead Thickness on the Fly | yes |

| Camera Process Monitoring (optional) | yes |

| Melt Pool Monitoring (optional) | yes |

| Closed Loop Control (optional) | yes |

* The deposition rate depends on laser power, hot wire, material type and print geometry.

ADDere’s High Power Coaxial uses a Laser Mech FiberWELD HR robot head with direct-cooled reflective optics that will minimize focus shift. It’s engineered for high-duty cycle production applications with medium to high-power, fiber-delivered lasers. The head’s advanced optical design permits wire to be fed directly into the beam path – right into the center of the melt pool. This allows the laser or cladding process to have total directional independence.

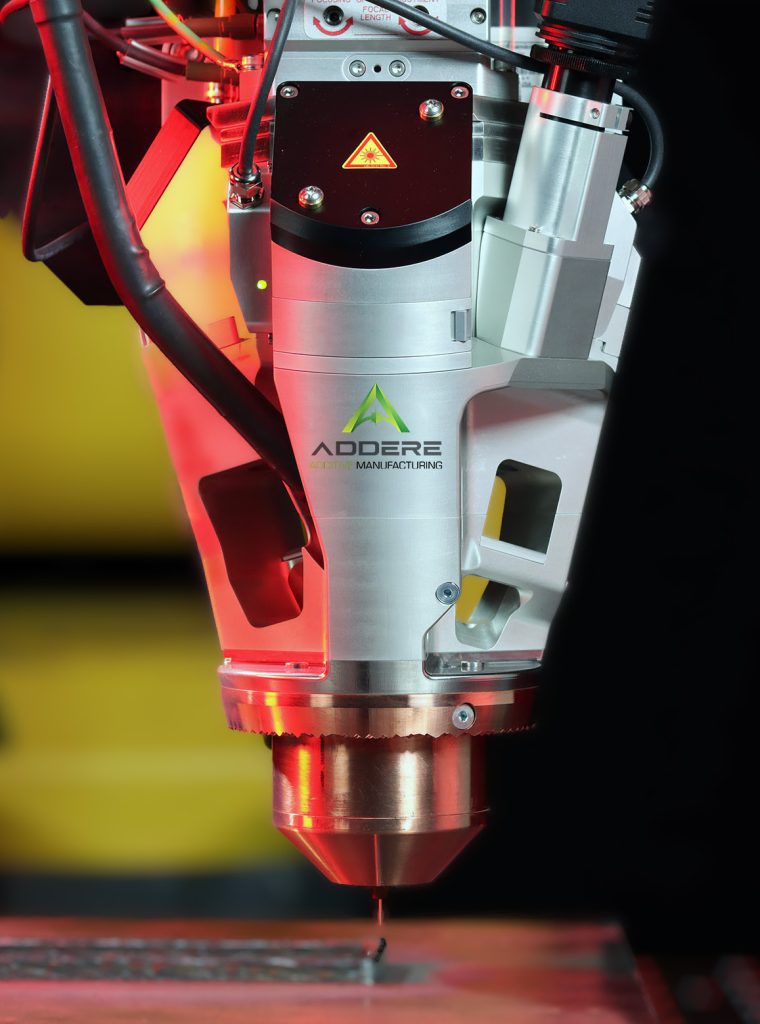

High Power Coaxial

| Laser Power (max) | 30kW Laser |

| Wire Size | 0.6-1.6mm (.023-.063) |

| Hot Wire Compliant | yes |

| Minimum Single Bead Thickness | <2mm |

| Maximum Single Bead Thickness | 15mm |

| Maximum Deposition Rate | 35lb/hr* |

| Water Cooled | yes |

| Vary Bead Thickness on the Fly | yes** |

| Camera Process Monitoring (optional) | yes |

| Melt Pool Monitoring (optional) | yes |

| Closed Loop Control (optional) | yes |

* The deposition rate depends on laser power, hot wire, material type and print geometry.

** Fixed laser spot, bead thickness variability limited.

ADDere’s High Power Coaxial uses a Laser Mech FiberWELD DH robot head with direct-cooled reflective optics that will minimize focus shift. It’s engineered for high-duty cycle production applications with medium to high-power, fiber-delivered lasers. The head’s advanced optical design permits wire to be fed directly into the beam path – right into the center of the melt pool. This allows the laser or cladding process to have total directional independence.

8kW Power Coaxial

| Laser Power (max) | 8kW Laser |

| Wire Size | 0.6-1.6mm (.023-.063) |

| Hot Wire Compliant | yes |

| Minimum Single Bead Thickness | <1mm |

| Maximum Single Bead Thickness | 15mm |

| Maximum Deposition Rate | 12lb/hr* |

| Water Cooled | yes |

| Vary Bead Thickness on the Fly | yes** |

| Camera Process Monitoring (optional) | yes |

| Melt Pool Monitoring (optional) | yes |

| Closed Loop Control (optional) | yes |

* The deposition rate depends on laser power, hot wire, material type and print geometry.

** Fixed laser spot, bead thickness variability limited.

ADDere’s Low Power Coaxial uses a Laser Mech FiberWELD DHc. This robot head is a compact material deposition head that is engineered for high-duty cycle production applications with low to high-power, fiber-delivered lasers. The head’s advanced optical design permits wire to be fed directly into the beam path – coaxially to the beam and right into the center of the melt pool. This allows the additive or cladding process to have total directional independence.

4kW Power Coaxial

| Laser Power (max) | 4kW Laser |

| Wire Size | 0.6-1.6mm (.023-.063) |

| Hot Wire Compliant | yes |

| Minimum Single Bead Thickness | <1mm |

| Maximum Single Bead Thickness | 15mm |

| Maximum Deposition Rate | 6lb/hr* |

| Water Cooled | yes |

| Vary Bead Thickness on the Fly | yes** |

| Camera Process Monitoring (optional) | yes |

| Melt Pool Monitoring (optional) | yes |

| Closed Loop Control (optional) | yes |

* The deposition rate depends on laser power, hot wire, material type and print geometry.

** Fixed laser spot, bead thickness variability limited.

ADDere’s Low Power Coaxial uses a Laser Mech FiberWELD DHc. This robot head is a compact material deposition head that is engineered for high-duty cycle production applications with low to high-power, fiber-delivered lasers. The head’s advanced optical design permits wire to be fed directly into the beam path – coaxially to the beam and right into the center of the melt pool. This allows the additive or cladding process to have total directional independence.

If you have any additional questions about the ADDere Engines or which engine best fits your additive manufacturing applications, please feel free to reach out to us.

do you want to learn more about ADDere's products and services?

From common metals to superalloys

Materials ADDere Prints

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from