ADDere Products

ADDere's large-scale Industrial Additive Manufacturing Solutions

ADDere Additive Manufacturing provides a number of best-in-class metal 3D printing products, from complete enclosed additive systems to just additive engines. ADDere’s products are based on clean, safe and reliable laser-wire additive manufacturing (LWAM) technologies that work on a fused metal deposition layering method that produces near net shaped results in the final printed part.

While the process may be simple to visualize, the performance of ADDere’s systems and engines lies in the purpose-built hardware and software that imbues the machines with best-in-class performance, safety and reliability. With performance not just in dimensional quality but in solid, repeatable metallurgical performance.

The solutions that ADDere provides make additive manufacturing ideal for highly demanding industries like aerospace, defense, petrochemical and more that require large-scale trustworthy, common and exotic superalloy metal printing.

Complete Systems

The ADDere additive manufacturing complete systems consist of three unique enclosures and capabilities. The Small Format System is a transportable, compact system. The Medium Format System is a larger but shop floor-friendly system. The Large Format System is a custom-built system ideal for large-scale manufacturing operations. All three systems are offered as enclosed units and with several configurations that can best suit your business’ manufacturing operations.

Additive Engines & Material Delivery

The ADDere additive engines are compatible with any ABB, KUKA or FANUC robot systems that are either brand new or currently in service. ADDere’s systems and engines include hot wire integration which improves deposition rates and metallurgical properties by pre-heating the wire.

The Software

The ADDere Runtime Software is a complete package that tracks the progress of the build and all the additive subsystems.

If you have any questions about the additive manufacturing solutions ADDere provides, please contact us today. Our additive experts will answer any questions you might have.

do you want to learn more about ADDere's products and services?

Best-in-class Printing Performance

Sample Parts

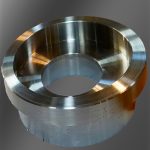

Rocket Thrust Chamber

Deposition Rate: 4 lbs. per hour

Total Built Time: 20 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter tall and 1 meter wide

System Used: ADDere Custom System

The final machined thrust chamber body has a sidewall thickness of 3mm with thicker walls in the combustion chamber.

Engine Exhaust/Intake Guarding

Deposition Rate: 4 lbs. per hour

Total Built Time: 40 hours

Material: Duplex Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

A complex part made from stainless steel. This part was built as a single solid component.

Turbine Blade

Deposition Rate: 4.5 lbs. per hour

Total Built Time: 30 hours

Material: Duplex Stainless Steel

Dimensions: 1.8 meters tall

System Used: ADDere Custom System

The completed turbine blade has a hollow interior and a 5mm wide sidewall. It is 1800 layers tall with a height variant of 0.5mm.

Propeller

Deposition Rate: 3 lbs. per hour

Total Built Time: 4 hours

Material: Carbon Steel

Dimensions: Each blade is 25 cm long

System Used: ADDere Standard System

Thin-walled metal components are 3D printed directly onto an existing steel part in this case a piece of steel round bar.

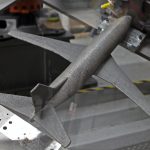

Freeform Design

Deposition Rate: 4.5 lbs. per hour

Total Built Time: 20 hours

Material: Stainless Steel

Dimensions: Wingspan is 1.6 meters long

System Used: ADDere Custom System

A large demonstration part with a hollow 6mm wall thickness.

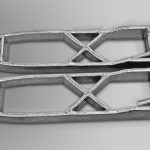

Wing Spar Cross-section

Deposition Rate: 6 lbs. per hour

Total Built Time: 1 hour

Material: Titanium Ti64

Dimensions: 50 cm long

System Used: ADDere Custom System

High-complexity 3D print in titanium. Cross-section aspects of 3D printing reduce construction times and make for a stronger overall part.

Thin Wall Curved Pipe

Deposition Rate: 6 lbs. per hour

Total Built Time: 3 hours

Material: Stainless Steet

Dimensions: 22 cm tall

System Used: ADDere Standard System

Custom-designed thin 4mm wall pipe that can be produced in different shapes and angles.

Fan Fins Assembly

Deposition Rate: 4 lbs. per hour

Total Built Time: 13 hours

Material: Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

Custom-designed fan fin assembly with a hollow core.

Large Gear

Deposition Rate: 20 lbs. per hour

Total Built Time: 10 hours

Material: Stainless Steel

Dimensions: 1 meter diameter

System Used: ADDere Custom System

A custom-designed solid gear or sprocket made entirely from stainless steel.

Mold Die Form

Deposition Rate: 6 lbs. per hour

Total Built Time: 3 hours

Material: Carbon Steel

Dimensions: 25 cm diameter

System Used: ADDere Standard System

Rapidly produce custom plastic injection molding die forms with additive manufacturing.

From common metals to superalloys

Materials ADDere Prints

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from