Part Finishing

Bringing our customers a one-stop shop for their additive manufacturing post-processing needs

Once ADDere completes the print, post-processing may be necessary to remove the substrate and finalize the part. Post-process finishing will help clean up any additional weldment burrs or sharp edges commonly formed during the printing process. A final sanding, polishing and paint application can also help protect the metal from natural corrosion and enhance the appearance of the part.

Once ADDere completes the print, post-processing may be necessary to remove the substrate and finalize the part. Post-process finishing will help clean up any additional weldment burrs or sharp edges commonly formed during the printing process. A final sanding, polishing and paint application can also help protect the metal from natural corrosion and enhance the appearance of the part.

In addition to the large-scale additive manufacturing process, ADDere optionally provides in-house part finishing. ADDere can provide grinding, deburring, sanding, welding, polishing and painting applications as part of the finishing process if desired or required by the customer. However, if the desire is for the part to be used as printed, accommodations can be made to keep the print near net shape.

Grinding

Grinding is a necessary operation in order to remove the completed part from the build plate substrate. ADDere takes this process into account when laying down the initial build layers.

Deburring

Deburring can remove rough edges and sharp protrusions that are the typical result of the printing process. Removing the burrs can improve the overall surface quality and appearance.

Sanding

By nature, 3D-printed parts have a relatively rough surface, which is the expected result of the additive manufacturing process. A sanding operation can smooth out the roughness formed by the metal deposition.

Welding

ADDere can perform additional welding operations on the completed part. Such as mounting additional pre-fabricated components, building onto the initial build or correcting imperfections.

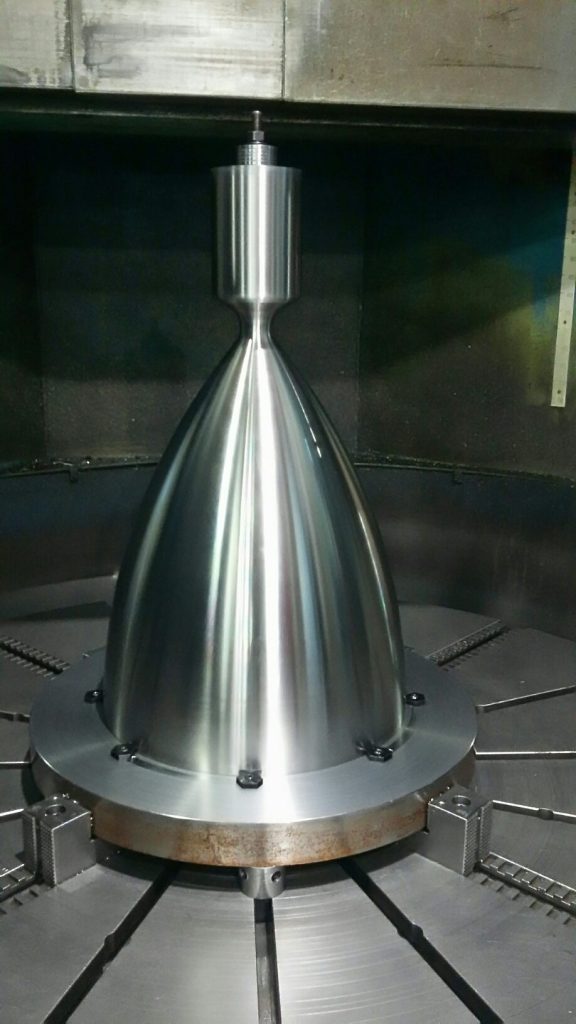

Polishing

A final polishing application enhances the appearance, prevents contamination, removes oxidation and creates a reflective surface, as well as deterring natural metal corrosion.

Painting

Besides being a cosmetic feature, a paint application will help protect the exposed metal from oxidation and natural corrosion and can extend the life of the part.

If your business is looking to have your 3D-printed parts run through one or all of the above post-processes, let us know. ADDere can accommodate virtually any material post-processing requests.

ADDere Print Services

Large components operate on their own economies from the high-volume parts made on laser-wire machines. Buying a large-scale additive manufacturing system without testing its abilities can feel like a gamble, especially when there are specialized requirements for the parts to be printed. Sometimes the number of components needed isn’t enough to rationalize the purchase of hardware needed to print the smaller runs. Many times it’s both.

In either case, ADDere understands the situation and provides metal printing as a service to manufacture these components on our machines. Whether to prove our system’s metal additive manufacturing abilities or to run parts without having to invest in 3D printing systems and training, ADDere can print your projects. Learn More…

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from