ADDere’s additive manufacturing process has many advantages over conventional manufacturing methods, such as reducing material waste, increasing design flexibility, new part functionalities and unique material properties. However, additive systems pose some challenges and risks, such as potentially high energy consumption and high initial costs. Therefore, it is important to consider the entire life cycle of the additive equipment and processes, from the initial integration of the system to the end-of-life considerations of the equipment.

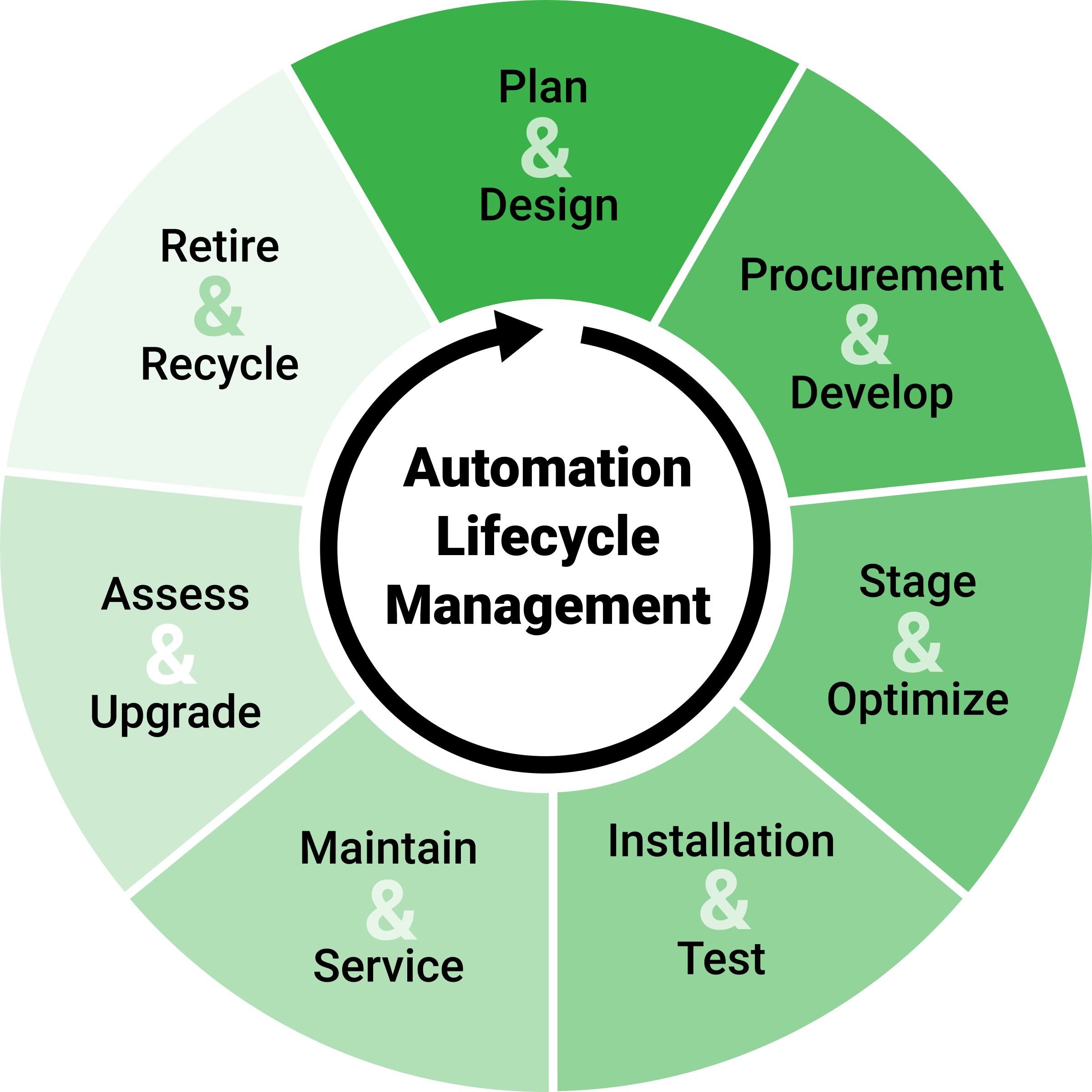

Life cycle management is a holistic approach that aims to optimize the environmental, social and economic performance of equipment and processes throughout their entire life cycle. Managing the life cycle helps stakeholders, such as manufacturers, engineers, operators and integrators, to identify and address the potential impacts and opportunities of additive manufacturing, and to improve its sustainability and competitiveness. Life cycle management also facilitates the integration of additive manufacturing with other technologies, such as factory automation systems and the circular economy.

The Life Cycle Assessment

One of the tools that can support life cycle management is life cycle assessment (LCA), which is a systematic method to quantify and compare the environmental impacts of products and processes from a cradle-to-grave perspective. By assessing the stakeholder’s manufacturing process, we can evaluate the economic and ecological benefits of ADDere’s additive technology, and identify the hotspots and improvement options along the value chain. For example, this assessment can help compare additive manufacturing with conventional manufacturing methods, optimize the build process parameters and post-processing needs, select the most suitable build materials, and evaluate the end-of-life scenarios and strategies for decommissioning the equipment.

ADDere’s additive manufacturing process can revolutionize the manufacturing industry and create new value for the economy. Life cycle assessment is an approach that can help additive manufacturing stakeholders improve the sustainability and competitiveness of their products and processes and foster the integration of additive manufacturing with other manufacturing processes.

However, life cycle assessment also requires some improvements and adaptations to cope with the complexity and uncertainty of additive manufacturing and to be integrated with other tools and methods that can address the financial and economic aspects of this new technology. By applying life cycle management and assessments to the additive manufacturing process, we can ensure that this revolutionary technology delivers not only technical innovation but also environmental and financial benefits.

What ADDere can do for you

The adoption of ADDere’s metal additive manufacturing processes represents a significant investment for any business. By considering all aspects, from acquisition to disposal, businesses can unlock the full potential of metal 3D printing while ensuring sustainability, efficiency and long-term financial return on investment. As the manufacturing landscape continues to evolve, a strategic approach to life cycle analysis and management will be indispensable for those looking to stay at the forefront of innovation.

ADDere provides complete systems and in-house ITAR-compliant print services that enable manufacturers to rapidly produce large-scale metal parts. If additive manufacturing is something your business has been seeking to pursue, then contact us today.