Metal additive manufacturing is a rapidly evolving technology and ADDere is at the forefront of it. An ADDere additive system can offer significant benefits to various industries, such as aerospace, automotive, defense and power generation. However, integrating additive manufacturing into an existing production workflow can be challenging, requiring careful planning, optimization and validation.

There are five key steps and considerations for implementing ADDere Additive Manufacturing in your production process.

Identify the right applications for ADDere

Not every part or product is suitable for additive manufacturing, so you need to evaluate the technical and economic feasibility of using ADDere for your specific needs. Some factors to consider are part geometry, material properties, functional requirements, quality standards, production volume, and cost-benefit analysis. Tools such as design for additive manufacturing (DfAM) software or readiness assessment frameworks can help you with this step.

Choose the appropriate ADDere System

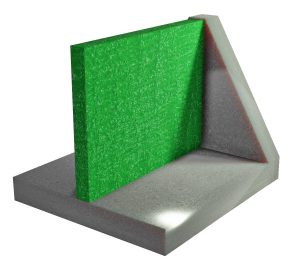

There are several different types of ADDere Systems and configurations available, each with its own advantages. Depending on the application, selecting the most suitable system is based on factors such as total build size, resolution, material compatibility, and post-processing requirements as well as how it will integrate into the existing manufacturing process.

Optimize the design and process parameters

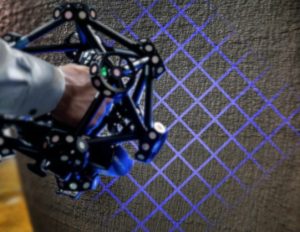

Optimizing the design and process parameters to ensure optimal print performance and quality of the final product. This may involve modifying the part geometry, orientation, support structures, layer thickness, scan speed, laser power and material. Simulation software and material trials are useful to test and validate different design and process scenarios and find the optimal print settings.

Establish a quality assurance process

Quality assurance is crucial for ensuring the reliability and safety of ADDere products, especially for critical applications such as aerospace or medical devices. Establishing a quality assurance process that covers the entire additive process chain, from material selection and characterization, to design verification and validation, to process monitoring and control, to post-processing and inspection. This will include complying with any relevant standards and regulations for your industry and application.

Integrate ADDere into your existing production workflow

Finally, you need to integrate ADDere into your existing production workflow in a seamless and efficient way. This may require modifying your production layout, logistics, maintenance schedule and more. You will also need to train your staff on how to operate and maintain the ADDere equipment and the robotic systems safely, as well as how to handle any issues or problems that may arise.

ADDere has proven experience integrating additive systems into our customers’ existing manufacturing processes. If you are looking to transition from a traditional casting process to additive manufacturing or are looking to produce one-off parts then contact us today. Our knowledgeable staff has the experience and know-how to walk you through the process.