Design for additive manufacturing (DfAM) is the process and method of designing products or components optimized for the additive manufacturing process. ADDere’s additive manufacturing process offers many advantages over traditional manufacturing methods, such as increased design freedom, reduced material waste and usage, lower production costs, and faster time-to-market. However, to fully exploit these benefits, designers need to consider the specific capabilities and limitations of additive manufacturing when creating their designs.

The Design Principles

Design for additive manufacturing involves applying various principles and guidelines to ensure that the design is suitable for ADDere. Some of these principles include the following:

Minimizing the number of parts and assemblies

ADDere allows for the creation of complex geometries that can integrate multiple functions into a single part, reducing the need for assembly and fastening operations. This can eliminate additional manufacturing costs and time associated with fastening components.

Reducing the need for support structures

Support structures are often required to prevent the deformation or collapse of overhanging features during the printing process. However, support structures consume additional material and time and must be removed after printing. Therefore, designers should avoid or minimize overhangs, or use self-supporting angles or lattice structures to reduce the need for supports.

Orienting the part for optimal printing

The orientation of the part on the build platform affects the quality, accuracy, and strength of the printed object. Designers should consider factors such as layer thickness, surface finish, dimensional accuracy and mechanical properties when choosing the best orientation for printing.

Choosing the appropriate metal alloy and process

Different additive processes and metal alloys have other characteristics. Designers should select the most suitable metal alloy and process for their design requirements, such as mechanical strength, thermal resistance, electrical conductivity, biocompatibility, etc. Learn more about metal alloys ADDere prints.

Optimizing the geometry for ADDere

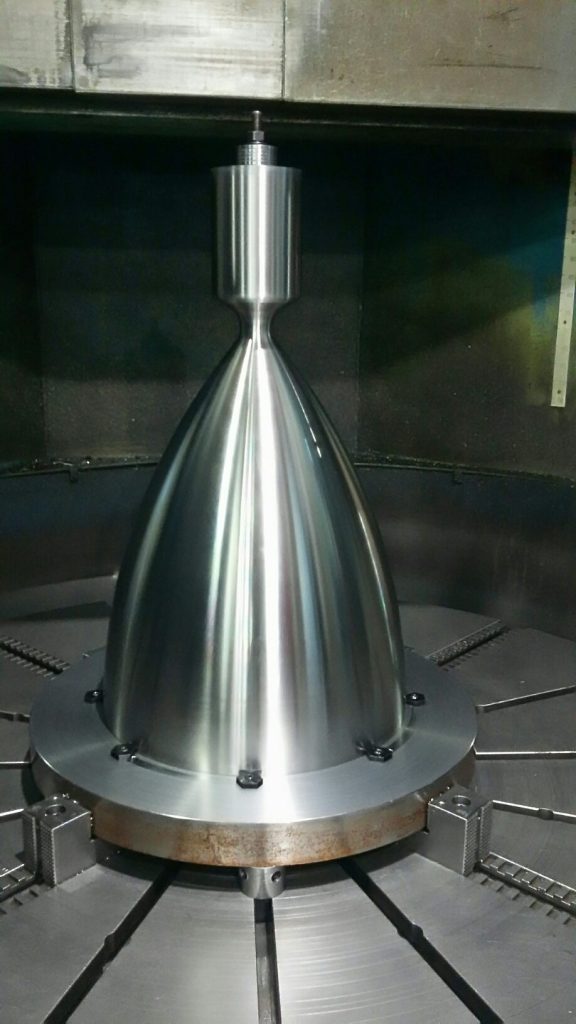

ADDere enables the creation of novel shapes and structures that are not possible or feasible with conventional manufacturing methods. Designers can use topology optimization, generative design, or biomimicry techniques to create lightweight, efficient, and functional designs optimized for additive manufacturing. Learn more about the design specifications.

Design for additive manufacturing is key to achieving successful and cost-effective additive applications. By applying DfAM principles and guidelines, designers can create products or components that are optimized for ADDere, enhancing their performance, functionality and aesthetics.

If you have an interest in printing large-scale metal alloy parts with ADDere, then contact us today. Our additive specialists can provide advice on the buildability of your design and how it can perform best during the additive manufacturing process.