How the ADDere Process Works

The ADDere Manufacturing Process

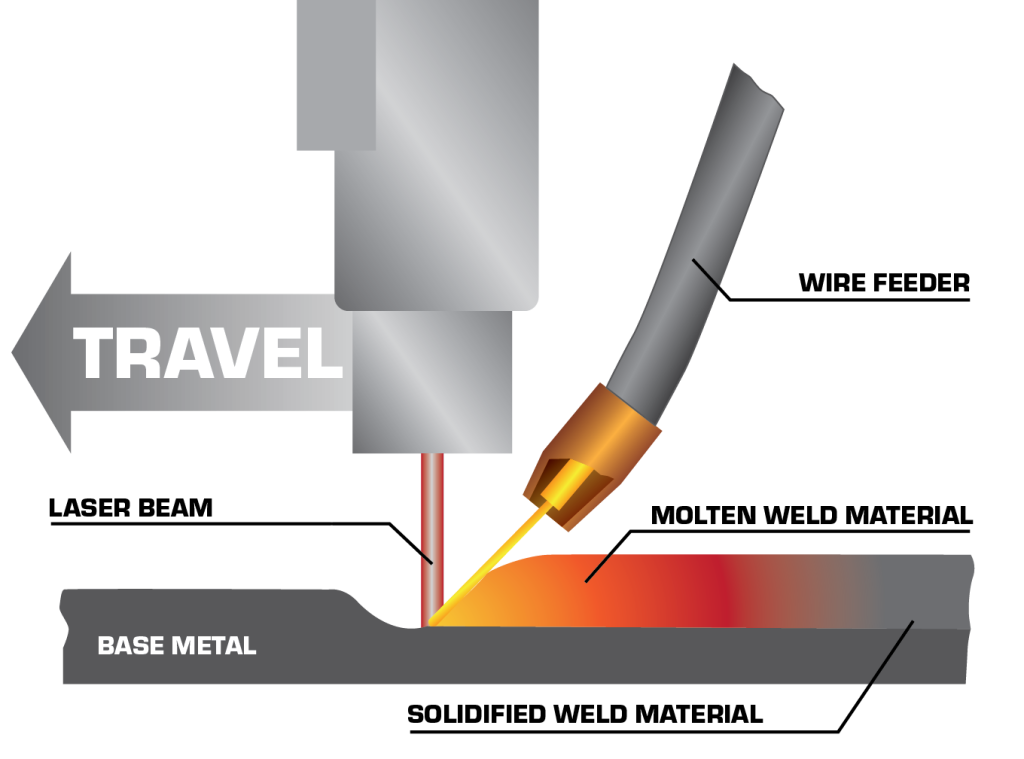

The ADDere laser-wire additive manufacturing (LWAM) system prints casting grade large-scale metal parts layer-by-layer in three dimensions. ADDere’s systems are controlled by a suite of high-speed, real-time, closed-loop sensors and purpose-built control software built around an industrial robot’s movement system.

The ADDere laser-wire additive manufacturing (LWAM) system prints casting grade large-scale metal parts layer-by-layer in three dimensions. ADDere’s systems are controlled by a suite of high-speed, real-time, closed-loop sensors and purpose-built control software built around an industrial robot’s movement system.

As with more common 3D printers that work in thermoplastics, ADDere simply sources the part construction and design from standard 3D modelled CAD drawings to produce the final near net shape metal-based part.

The Build Volume

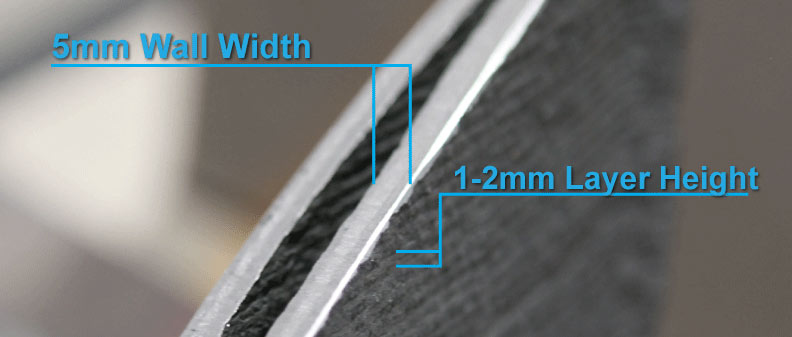

ADDere’s additive manufacturing systems have a build volume that starts at around 15 cm (6 inches) cubed and scales upwards to meters for custom large-scale productions. To achieve the best results in speed and efficiency builds typically have a layer height of around 1-2mm, and a wall thickness starting at about 5mm.

The Components of ADDere

The ADDere additive manufacturing process is built around four main components: the laser heat source, the material delivery system, the motion control system and the ADDere Runtime Software control system.

The Laser Heat Source

The Material Delivery System

The Motion Control System

The Runtime Software

Can ADDere help your business?

The demand for exotic superalloy metals has been rapidly growing in the aerospace, defense, marine, oil & gas and petrochemical industries. These exotic metals are inherently expensive and difficult to machine or cast on a large scale. However, with ADDere’s LWAM process, individual parts can be manufactured faster and more cost-effectively by eliminating material waste that would otherwise result from traditional machining or casting.

If ADDere’s high-quality large-scale metal additive manufacturing process sounds like something that your firm would benefit from, whether it’s in aerospace, defense, oil & gas or any other industry, contact us today. The ADDere laser-wire additive manufacturing process can produce large-scale builds in a wide range of sizes and materials near net shape to fit all your manufacturing needs.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from