Low-Run – Large Part Production

ADDere specializes in low-volume runs of large components

ADDere is designed to 3D print near net shape metal parts that offer casting-grade quality using a laser wire additive manufacturing process. In the time it takes conventional casting companies to merely build the casting cores, our additive manufacturing system can create complete components ready for finish machining. The time and cost reductions using the ADDere metal 3D printing system could mean the difference between profitability and costs being prohibitively expensive to make low volume, large size parts.

The ADDere system arrives at a near-net-shaped, casting-grade part in far fewer steps than conventional casting processes. Going from CAD geometry to printed part side-steps the need to create a pattern, ram a mold, pour and de-gate a part. Instead, the 3D print is ready for finish processes right out of the printer. This can reduce costs involved with smaller run parts as the need for labor to fabricate pattern work or to manually grind and de-flash castings.

For components that also see lower runs due to high customization or rapid developments, using ADDere additive metal manufacturing systems, makes changes to large-size metal components less time-consuming and expensive. Changes can be made in the CAD files before printing, instead of having to update or rebuild casting patterns before casting parts.

If your business is looking for a fast, cost-effective way for low-run large-part manufacturing, please contact us today. The ADDere large-scale additive manufacturing process can print in sizes and materials to fit your business’s needs.

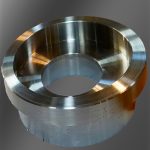

Mold Form

Three-hour 3D laser-wire additive build time reduced subtractive processes. The carbon Steel metal printing process allowed customers to move into production faster and more cost-effectively than conventional processes.

Deposition rate: 6 lbs./h

Build time: 3 hours

Material: Carbon Steel

Equipment used: ADDere Standard System

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from