Why Additive Manufacturing

Why is the ADDere Laser-Wire Additive System the Future of Manufacturing?

ADDere’s best-in-class laser-wire additive manufacturing process revolutionizes the manufacturing industry by drastically improving the time to market, reducing the cost of materials, providing consistent performance and eliminating scrap waste.

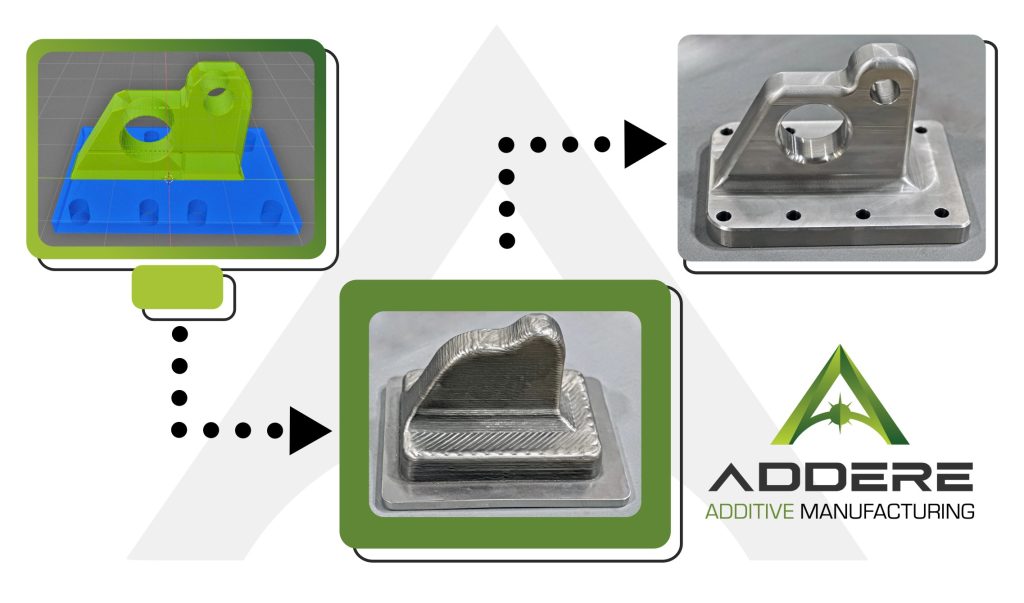

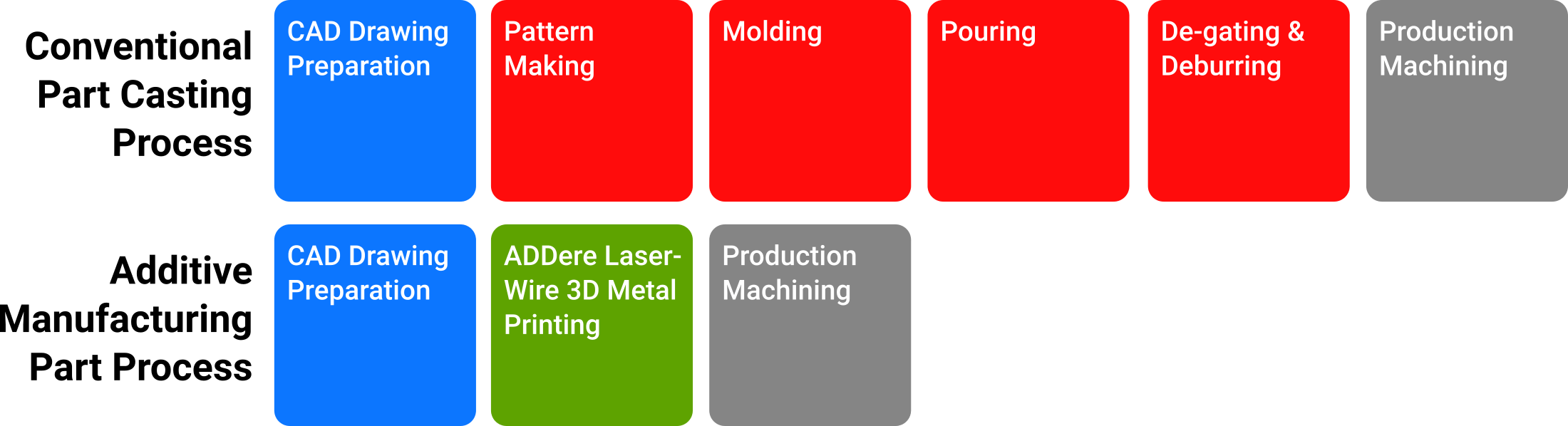

Time to Market: Casting vs. Additive Manufacturing

A dramatic reduction in time, from the design phase to the completion of the part, is possible with ADDere’s Additive Manufacturing products and services. Parts and processes that could take anywhere from months to even years to create now have the capacity to be accomplished within days or even hours.

Design-to-part usually involves multiple steps that rely on each other’s completion. This process includes several aspects: design approval/lock design, ordering, designing and building fixtures, casts or forms, sourcing of material, casting or forging parts and machining. With conventional processes currently available in the market, delivery times of up to one year are a common time frame for these steps and components.

With the ADDere Additive Manufacturing process, time-intensive iterative steps like the component design or fixture building can be greatly reduced. Designs can be sent directly to additive manufacturing systems for processing. This process allows for a much faster design cycle as components and fixtures can be tested at scale and in the materials specified for end use. With ADDere’s systems that could mean even Titanium, Inconel or other exotic metals.

ADDere also offers time advantages over conventional manufacturing processes. Complex parts that would have required casting could be 3D printed in a variety of metals, side-stepping the many steps involved in common casting processes. The laser wire additive system has benefits over milling, especially when considering high-complexity products where 3D printing opens the possibility for geometries that would be difficult to impossible with current milling technologies.

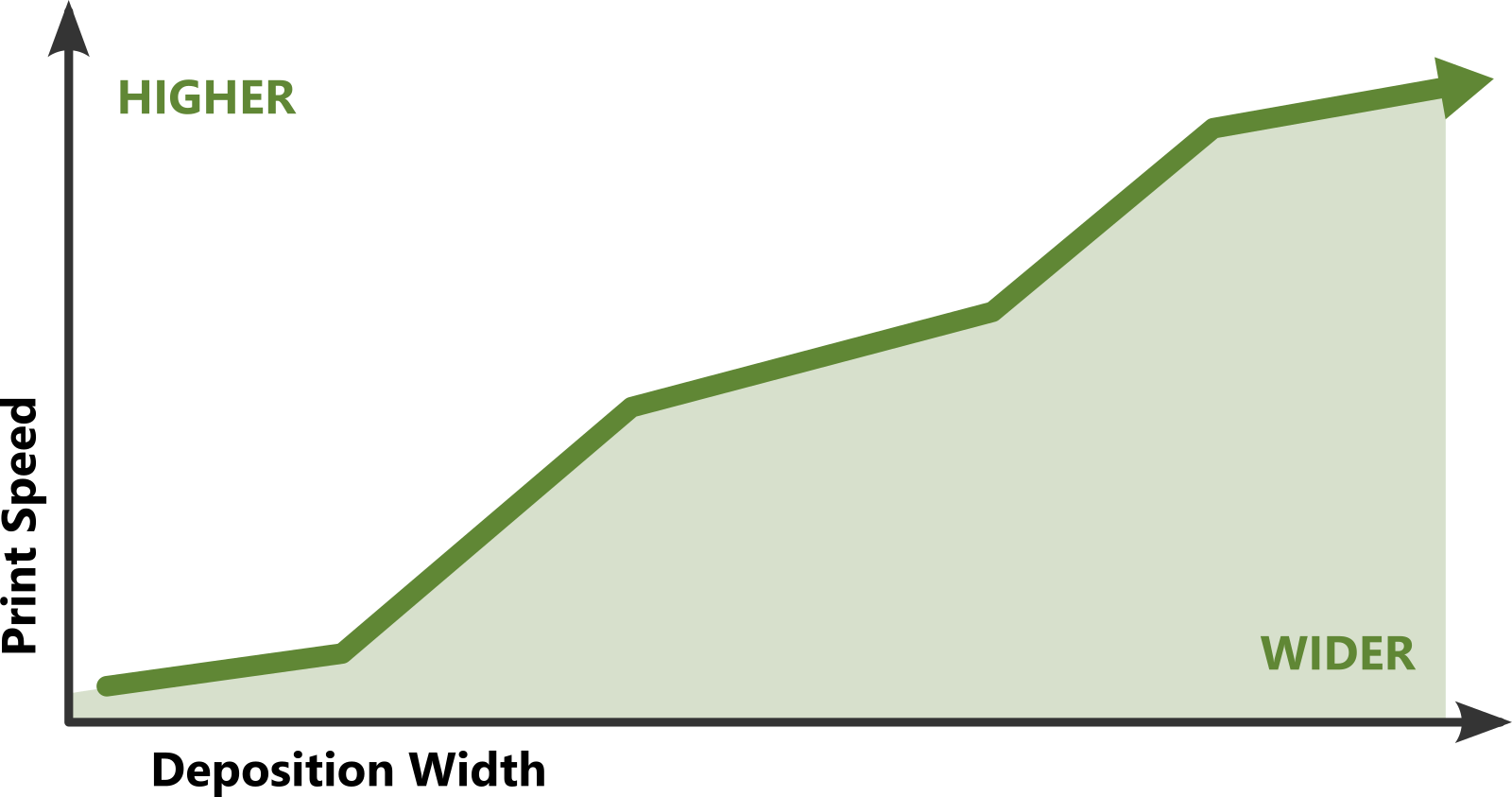

With the ADDere Additive Manufacturing systems, laser-wire metal deposition rates can range from 7 to 22 lbs per hour. These rates will change depending on the metal type and the geometry of the part being built.

Cost of Materials: Powder vs. Wire Based Deposition

Using reliable laser-wire metal deposition, the additive manufacturing process has the ability to save large amounts of material cost. Close to 100% of the material used in ADDere’s additive metal 3D printing process goes into the component being printed, whereas in a powder-based process material waste is substantially more and the material is prone to impurities.

Typically the cost for the same quantity of material in powder is typically double that of the cost for wire. For more exotic and more expensive materials, this can have a great impact on the total cost of the component. For example, titanium wire costs around 40% of the cost of powder per kilogram.

Performance: Powder vs. Wire Based Deposition

While powder-based deposition works well when producing small intricate parts, powder-based doesn’t provide the speed and metallurgical purity that wire-based would provide. Moreover, powder is an inherently less safe material to work with, being more flammable and more prone to moisture and other impuraties. When printing large-scale parts, wire-based deposition runs at much higher print speeds than powder.

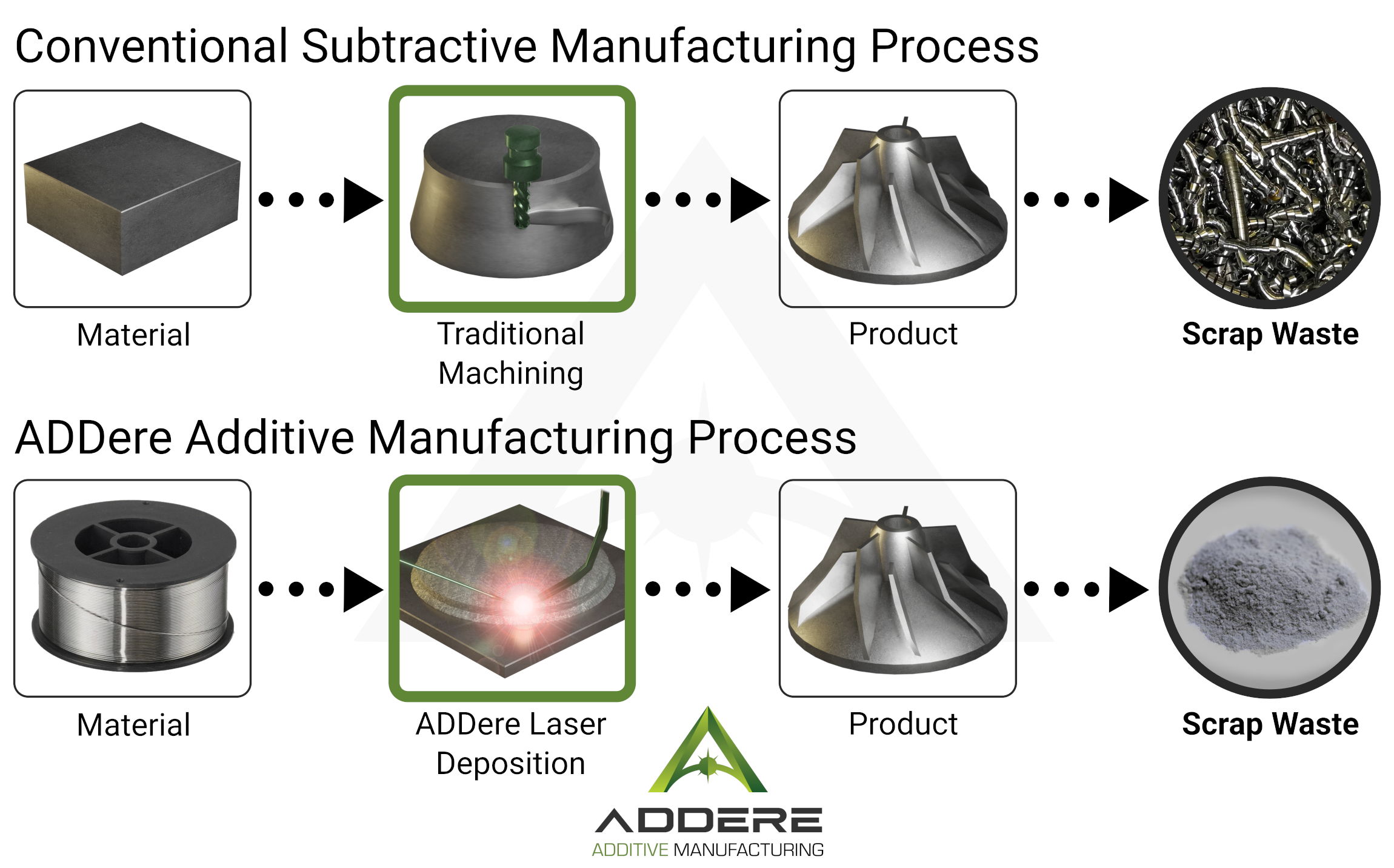

Less Scrap Waste: Subtractive vs. Additive Manufacturing

Conventional subtractive manufacturing processes from a single block of metal require removing a substantial amount of material to build the part leading to a large amount of scrap waste. Whereas additive manufacturing creates parts that are near net shape and utilize nearly 90% of the material. The final part requires a minimal amount of machining to make the part production-ready.

Can ADDere Help Your Business?

If ADDere’s high-quality large-scale metal additive manufacturing process sounds like something that your firm would benefit from, whether it’s in aerospace, defense, oil & gas or any other industry, contact us today. The ADDere laser-wire additive manufacturing process can produce large-scale builds in a wide range of sizes and materials near net shape to fit all your manufacturing needs.

do you want to learn more about ADDere's products and services?

What's going on at ADDere

Latest Blog Posts

Are 3D Printed Metal Parts Produced with ADDere Strong?

ADDere’s additive manufacturing has revolutionized the production of strong metal-alloy parts, offering unprecedented flexibility and precision. One of the most exciting developments in this field

Mitigate Tariffs on Steel by Reshoring Your Manufacturing with ADDere

When it comes to large-scale metal parts manufacturing, ADDere can be a lifesaver for many businesses concerned with high import prices of steel. For decades,

Harnessing ADDere’s Additive Manufacturing Process for Next-Generation Drones

Industrial applications of drones are soaring to new heights in 2025. From utilities and infrastructure inspection to agriculture and defense applications are industries that will

From Concept to Core: How ADDere Transforms Nuclear Reactor Components

Additive manufacturing has been gaining traction in the nuclear energy industry. The development and maintenance of nuclear reactors demand components that meet stringent safety standards

White Paper: The Impact of Additive Manufacturing on Cost, Efficiency & the Future

ADDere’s metal laser-wire additive process is a proven technology for producing complex large-scale metal parts for the defense and aerospace industries. With increasing interest in

Cost-Benefit Analysis of ADDere’s Additive Manufacturing Process

ADDere’s metal additive manufacturing process has transformed the manufacturing landscape by enabling the production of complex parts with unprecedented precision. Additive manufacturing has evolved from